The engineering behind Precision aluminum casting for industrial applications

The Duty of Aluminum Foundries ahead of time Lightweight Manufacturing Solutions

Aluminum shops substantially add to the development of lightweight production remedies. Their cutting-edge spreading technologies generate high-strength, light-weight components necessary for industries like automobile and aerospace. This advancement not just boosts product efficiency however also promotes sustainability with making use of recycled materials. As these shops adapt to arising techniques and innovations, they lead the way for future growths in making performance and environmental duty. What lies in advance in this transformative trip?

The Advantages of Lightweight Materials in Production

As industries increasingly look for effectiveness and sustainability, the adoption of lightweight materials in manufacturing has become a crucial strategy - Precision aluminum casting. These materials, specifically aluminum and composites, offer numerous benefits that enhance manufacturing procedures and product performance. Largely, their decreased weight adds to reduce power usage during transportation and operation, leading to substantial expense financial savings

Furthermore, lightweight products help with the design of more complex geometries, enabling higher development in item development. This versatility typically causes enhanced functionality and efficiency, dealing with the advancing demands of modern customers.

In addition, the usage of lightweight materials can improve the durability of items due to their resistance to deterioration and tiredness. This sturdiness not just reduces maintenance expenses yet likewise sustains sustainability campaigns, as longer-lasting products contribute to much less waste. To sum up, the benefits of lightweight materials are crucial in driving effectiveness, development, and environmental duty in production.

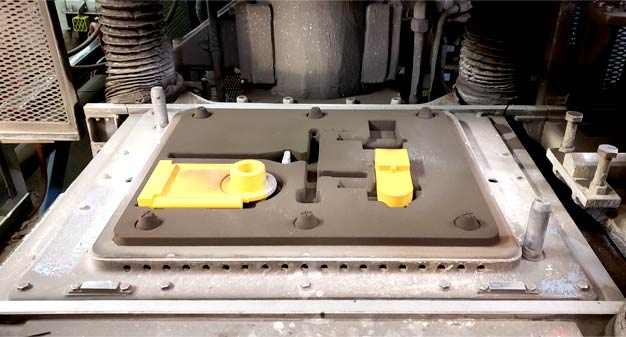

Innovations in Aluminum Casting Technologies

Current improvements in light weight aluminum casting innovations are changing the manufacturing landscape, especially in the production of lightweight elements. Advancements such as high-pressure die casting and vacuum die casting have significantly boosted the accuracy and surface coating of light weight aluminum parts - Aluminum Casting Company. These methods permit the creation of intricate geometries while minimizing material waste and boosting mechanical properties

Furthermore, the execution of real-time monitoring systems assures top quality control throughout the casting procedure, causing even more regular item results. Jointly, these advancements not only enhance the performance of aluminum parts however additionally sustain the industry's shift towards even more sustainable manufacturing practices.

Applications of Light Weight Aluminum Components in Different Industries

While light weight aluminum elements have long been utilized in different markets, their versatility and light-weight properties remain to drive cutting-edge applications across industries such as automobile, aerospace, and construction. In the automotive sector, aluminum is progressively made use of for engine blocks, wheels, and body panels, boosting gas effectiveness and efficiency. Aerospace producers take advantage of aluminum for aircraft frameworks and components, profiting from its strength-to-weight ratio to boost fuel economic situation and haul ability.

In the building field, light weight aluminum is preferred for window frames, roofing, and architectural components, offering toughness and resistance to deterioration while reducing total building weight. Furthermore, the electric and electronic devices markets benefit from light weight aluminum's conductivity and light-weight nature, utilizing it in wiring, units, and heat sinks. These varied applications highlight the vital role of light weight aluminum elements, which not only fulfill sector needs however likewise add to innovations in item layout and performance across multiple areas.

Sustainability and Energy Efficiency in Aluminum Foundries

The aluminum foundry sector plays an essential duty in advertising sustainability and energy effectiveness, specifically as need for lightweight components proceeds to expand across various fields. Factories are progressively taking on eco-friendly methods, such as using recycled light weight aluminum, which considerably lowers power intake and greenhouse gas exhausts compared to key light weight aluminum manufacturing.

Advancements in casting innovations boost power effectiveness by maximizing the melting processes and minimizing waste. Techniques like die casting and financial investment spreading enable for exact material use, minimizing excess and scrap.

In addition, several foundries are buying renewable resource sources to power operations, additionally reducing their carbon footprint. Implementing power administration systems makes it possible for shops to enhance and monitor power usage, ensuring they operate at peak performance.

Future Fads in Lightweight Production Solutions

Exactly how will arising innovations form the future of light-weight manufacturing solutions? Innovations such as advanced products, automation, and additive manufacturing are readied to redefine Related Site manufacturing procedures. The combination of smart production innovations, consisting of the Internet of Points (IoT) and expert system (AI), will enable real-time surveillance and click here for more info optimization, enhancing performance and minimizing waste.

As sustainability continues to be a paramount issue, lightweight solutions will progressively concentrate on reusing and recycling materials, aligning with circular economy concepts. This evolution in light-weight manufacturing will not only boost product performance but likewise add to environmental goals, guaranteeing that the market remains affordable in a quickly changing market landscape.

Regularly Asked Concerns

How Do Light Weight Aluminum Foundries Ensure Quality Assurance in Manufacturing?

Aluminum shops guarantee top quality control in manufacturing through extensive testing, standardized procedures, and continuous surveillance - Aluminum Foundry. They execute knowledgeable employees and advanced innovations to keep uniformity, decrease flaws, and meet industry requirements throughout the manufacturing procedure

What Are the Main Challenges Encountered by Light Weight Aluminum Foundries?

Light weight aluminum factories deal with difficulties such as rising and fall basic material prices, keeping manufacturing performance, making sure consistent quality, adapting to technical developments, and conference environmental laws, every one of which influence their total functional effectiveness and competition in the market.

Just How Does Light Weight Aluminum Recycling Influence Shop Operations?

Light weight aluminum reusing significantly improves shop operations by reducing basic material expenses, lessening energy usage, and reducing environmental effect. This sustainable practice makes it possible for foundries to boost effectiveness while meeting boosting need for light-weight, high-performance light weight aluminum products.

What Abilities Are Needed for Employees in Aluminum Foundries?

Workers in aluminum foundries call for skills in metallurgy, machining, quality assurance, and safety practices. Proficiency in operating equipment, comprehending alloy residential or commercial properties, and analytical are likewise crucial for reliable manufacturing and keeping high safety and security standards.

Just How Do Aluminum Foundries Handle Waste Monitoring?

Aluminum shops manage waste through reusing scrap metal, utilizing effective waste partition methods, and sticking to environmental regulations. They implement lasting practices to decrease garbage dump contributions, official website making certain that harmful materials are dealt with sensibly.

Light weight aluminum foundries considerably contribute to the development of lightweight production solutions. Recent developments in light weight aluminum spreading technologies are changing the manufacturing landscape, specifically in the production of light-weight components. While light weight aluminum elements have long been made use of in different industries, their adaptability and lightweight buildings continue to drive ingenious applications throughout fields such as vehicle, aerospace, and construction. Furthermore, the electric and electronic devices markets benefit from aluminum's conductivity and lightweight nature, utilizing it in wiring, rooms, and heat sinks. The light weight aluminum shop industry plays a critical role in advertising sustainability and energy effectiveness, especially as demand for light-weight parts proceeds to grow throughout numerous industries.